Breakdown Maintenance

Solar plants are precision investments. Every solar module, inverter, and transformer in your facility is designed to generate electricity and create revenue. But when a breakdown occurs, generation halts—and with it, your income. Unlike other industries, downtime in a solar plant directly translates into financial loss, eroding confidence in your operations and raising long-term risks.

This is where SolarTech Breakdown Maintenance comes in. Our services go beyond quick repairs—we restore your plant efficiently, investigate root causes, and implement solutions that prevent recurring failures. From inverters and DC faults to transformers, HT panels, and communication systems, we take full responsibility until your plant is back to optimal operation.

The True Cost of a Breakdown

Unexpected breakdowns in a solar plant are more than technical challenges—they are business-critical events. Their impact can be felt in multiple ways:

- Lost Energy Generation: Every hour your plant is offline is electricity that is not fed into the grid. For large plants, this can mean thousands of dollars in lost revenue.

- Decreased Trust: Investors, customers, and stakeholders expect reliability. Frequent or prolonged downtime can undermine confidence and affect future opportunities.

- Escalating Risk: Ignoring or delaying repairs can allow minor faults to escalate into major equipment damage, increasing maintenance costs and the risk of permanent losses.

Downtime is expensive, but with the right approach, it can be minimised and effectively managed.

What Is Breakdown Maintenance?

Breakdown maintenance, also called corrective maintenance, involves addressing equipment failures immediately after they occur. Unlike preventive maintenance, which is planned and routine, breakdown maintenance is reactive. It requires:

- Rapid Assessment: Identifying the faulty component quickly.

- Precise Repair: Fixing or replacing the failed component according to technical and manufacturer standards.

- Verification: Ensuring the plant returns to stable operation and continues generating electricity safely.

In solar plants, breakdown maintenance often covers:

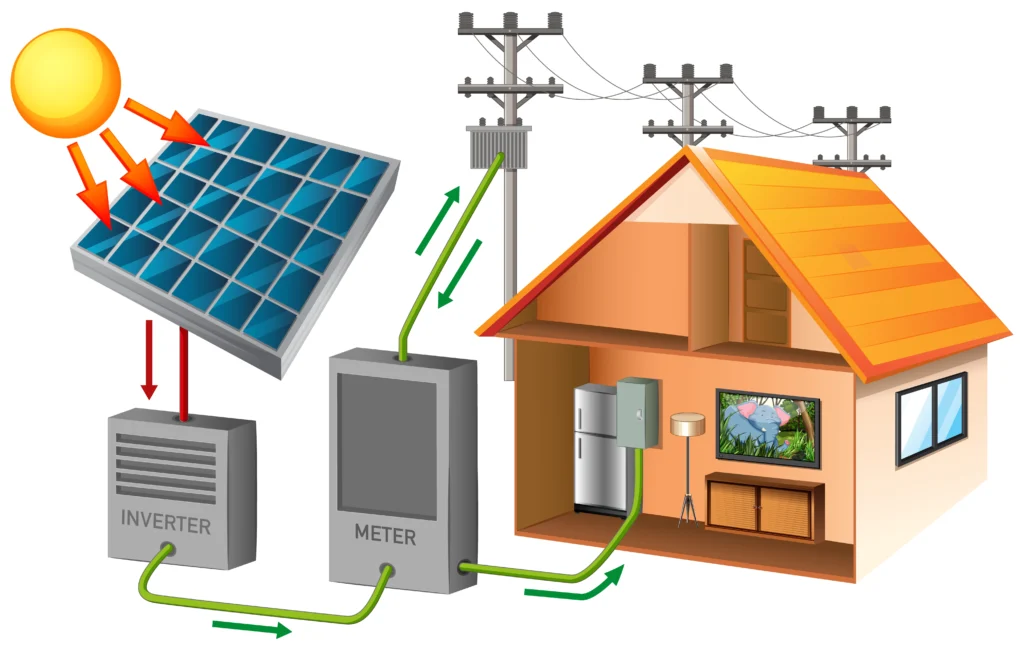

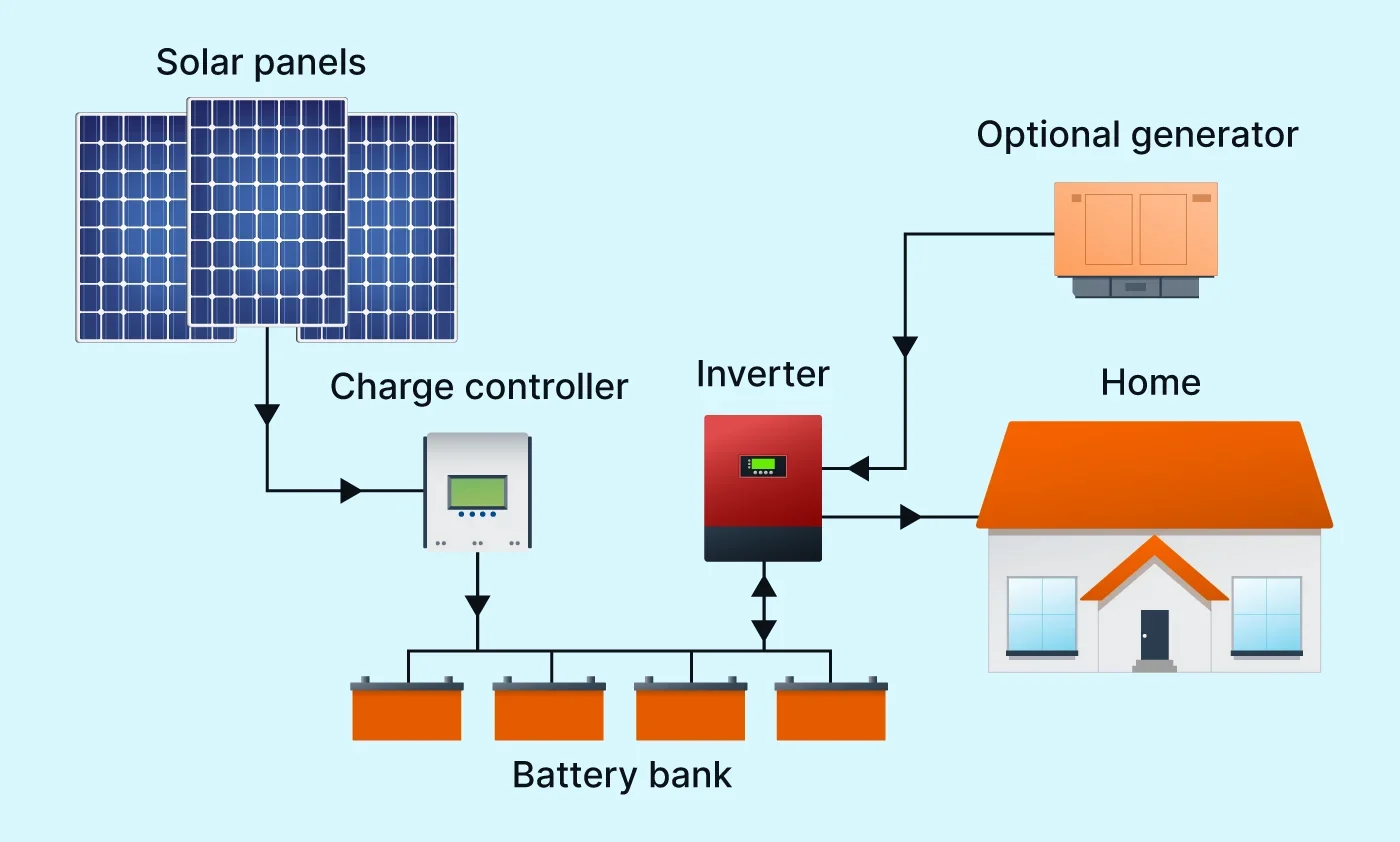

- Inverters: These devices convert DC power from modules into AC for the grid. A trip or fault stops power generation instantly.

- DC Lines and Faults: Problems in cabling or connections can trigger automatic shutdowns, requiring careful tracing and replacement.

- Transformers & HT Panels: Electrical distribution systems are sensitive; a fault can compromise the entire section of a plant.

- Communication Systems: Monitoring and control failures don’t always stop generation but prevent timely fault detection, prolonging downtime.

Every type of fault needs swift, expert attention to minimise loss and prevent recurrence.

How SolarTech Handles Breakdowns

At SolarTech, we don’t just “patch up” problems. Our approach is designed to restore full plant operation while protecting long-term performance. Here’s how we approach breakdown maintenance:

1. Immediate Response

When a fault occurs, our engineers are ready to act. Through a combination of remote monitoring and on-site assessment, we quickly determine the severity and source of the problem. Pre-deployed tools and replacement parts allow repairs to start without delay.

2. Root Cause Analysis

A short-term fix may restore generation temporarily, but without understanding the underlying issue, failures often return. We use detailed diagnostics to identify the real cause, whether it’s a software error in the inverter, insulation failure in DC lines, or a fault in transformers or HT panels.

3. OEM-Compliant Repairs

SolarTech follows manufacturer guidelines for all repairs and replacements. This ensures that equipment warranties remain intact, repairs are safe, and the plant continues to operate as designed.

4. Complete Ownership

Unlike standard service providers that close tickets once a repair is made, we stay with your plant until the issue is fully resolved. After repairs, we monitor the system to confirm that generation is stable and that the problem will not recur.

5. Plant-Owner Perspective

Our team treats every plant as if it were our own. Every decision, from troubleshooting to component replacement, prioritises long-term performance and risk reduction—not just short-term fixes.

Common Breakdown Scenarios

- Inverter Trips: Inverters are the heart of solar plants. Trips stop electricity conversion. We diagnose, repair, and recalibrate inverters to restore stable operation.

- DC Faults: Faults in DC wiring or modules can trigger shutdowns. We trace the fault, replace damaged components, and test the system for safe operation.

- Transformer Failures: Transformers step up voltage for grid integration. We inspect, repair, or replace components to restore reliable performance.

- HT Panel Issues: High-tension panels are sensitive. Our technicians perform testing, replace faulty parts, and prevent cascading failures.

- Monitoring System Failures: Effective monitoring allows operators to detect faults quickly. We repair or replace communication hardware and restore full system visibility.

Why SolarTech Is Different

- Rapid Recovery: Quick diagnosis and repair minimise downtime.

- Technical Expertise: OEM-aligned procedures ensure safe, reliable repairs.

- Proactive Verification: We confirm post-repair stability, preventing repeated failures.

- Accountability: We take responsibility until your plant is back to full operation.

- Long-Term Focus: Our interventions protect plant performance for years, not just hours.

Beyond Repairs: Securing Performance

Breakdown maintenance isn’t just about fixing problems—it’s about protecting your investment and ensuring continuous energy production. Our services are designed to:

- Reduce Recurring Failures: By addressing root causes, we prevent repeated downtime.

- Extend Equipment Lifespan: Repairs following OEM standards ensure equipment performs reliably over time.

- Maximise Energy Output: A fully functional, well-maintained plant generates the electricity you planned for.

- Build Confidence: Reliable operations enhance credibility with investors, stakeholders, and regulators.

When Every Minute Counts

In solar energy, every minute of downtime matters. For corporate, industrial, and utility-scale solar plants, unexpected shutdowns can have cascading impacts on revenue and operational credibility. SolarTech ensures that when breakdowns occur, they are handled efficiently, professionally, and permanently.

Choosing SolarTech means choosing a partner who treats your plant like their own, acts swiftly when faults arise, and ensures that your solar assets continue to generate value day after day.

FAQs

1. What is breakdown maintenance for solar plants?

Breakdown maintenance is the corrective action taken when equipment in your solar plant fails unexpectedly. It includes diagnosing the issue, repairing or replacing faulty components, and verifying that the system returns to stable operation.

2. How quickly can SolarTech respond to a breakdown?

We prioritise rapid response. Our engineers can begin remote diagnostics immediately and are dispatched to your site as quickly as possible to minimise downtime.

3. Do you follow OEM guidelines during repairs?

Yes. All repairs and replacements follow Original Equipment Manufacturer (OEM) standards, ensuring safety, reliability, and warranty compliance.

4. Which components does SolarTech service?

We handle a wide range of equipment, including inverters, DC lines and faults, transformers, HT panels, and communication or monitoring systems.

5.What makes SolarTech different from other service providers?

Unlike standard providers who “close tickets,” SolarTech takes full ownership until your plant is stable and verified. We treat every plant as our own and focus on long-term performance, not just short-term fixes.

6. Can breakdown maintenance prevent future failures?

Absolutely. Our approach includes root cause analysis and proactive solutions that reduce the likelihood of recurring breakdowns and extend equipment lifespan.

7. Will downtime affect my revenue?

Downtime always impacts revenue, but SolarTech’s fast response and precise repair minimise this loss, helping restore generation as quickly as possible.

8. Do you provide post-repair monitoring?

Yes. We continuously monitor your plant after repairs to ensure stability and prevent repeated issues, giving you confidence in long-term performance.